| Side Guides |

3" Wheels

|

4" Wheels

|

6" Wheels

|

Roller Turn Rollers |

|

|

|

|

|

|

|

|

Quantum Advantage

|

|

Quantum wheels are manufactured exclusively by Meter U.S.A., Inc. Click the logo to the left to visit their website

|

|

|

Quantum wheels are superior because of the material used in their construction and the alignment of their inner races. With poor material and poor inner race alignment, trolleys wheels can prematurely fail

|

|

How a Wheel Works

|

|

When traveling on a horizontal plane, only a small portion of the inner race sees any pressure. Since the inner race is stationary and does not turn, that same small portion of the inner race is the only part of the inner race that wears.

|

|

|

The interactive movie on the right will give you a visual explanation.

|

|

The Importance of Good Material

|

|

A through-hardened, chrome bearing steel is essential for long wheel life. The Quantum wheel is constructed with 52100 bearing steel in the outer race, inner race, and balls.

|

|

Through hardened is just that, hard all the way through. Case hardened parts are only hard to a certain depth. Once that depth is reached, parts wear out exponentially.

|

|

|

CASE HARDENED |

THROUGH HARDENED |

|

|

The Quantum™ is the only 100% SAE 52100 chrome steel constructed trolley wheel manufactured in North America.

|

|

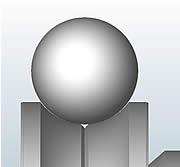

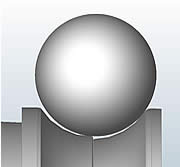

If the inner races of a full ball compliment load wheel are not aligned exactly, the balls will not seat properly.

|

|

|

Quantum load wheel inner race alignment |

Non Quantum load wheel inner race alignment |

|

|

|

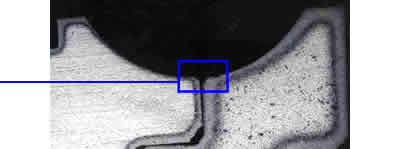

Below are pictures of actual load wheel failures caused by case hardened material and misalignment of the inner races.

|

|

|

|

|

| In the above pictures, the ball was riding on the edge of one inner race. This caused the case hardened steel to be crushed. Wear proceeded exponentially once the case was broken through. |

Notice the left piece of the inner race has worn through the case hardened shell. The piece on the right shows considerably less wear |

|